Basecrete Technologies has built its reputation on innovation in waterproofing and surface protection for the pool and construction industries. Under the leadership of President Vito Mariano, the company has consistently sought ways to improve longevity, durability, and ease of application for builders and contractors. This year, Basecrete is excited to add three standout products to their lineup—Nano-Set, Suede, and a new fiberglass mesh system within Basecrete Xtreme—each designed to address long-standing challenges in plaster, waterproofing, and bonding.

Basecrete Introduces Three Exciting New Products

Mariano has spent decades refining solutions for plaster and waterproofing. With multiple patents to his name, his focus has always been on developing products that improve performance while simplifying the applicator’s job. “I’ve been working with pool plaster, even with my patents, for many years. I know how the cement aggregate works inside swimming pools,” Mariano explained. His latest releases are a continuation of that philosophy—products that tackle recurring issues like pigment loss, permeability, callbacks, and labor inefficiencies.

Nano Set: Enhancing Pool Plaster from the Inside Out

Solving Plaster Challenges

Nano-Set is an additive formulated to reduce pigment loss, improve workability, and strengthen plaster finishes. “It reduces the pigment loss of the plaster, especially the plaster dust. It allows more cream for workability, which minimizes callbacks from customers,” Mariano said. By reinforcing the plaster matrix, the product aims to eliminate common frustrations contractors and homeowners face after installation.

Feedback from the Field

At Pool Magazine, we often check in with the top applicators and installers in the industry to gauge how new products are performing in real-world conditions. One of those voices is Jason Evans, a respected contractor who was previously featured in Pool Magazine for his work on the iconic Hard Rock Seminole resort pool project. Evans has also been an early adopter of Basecrete’s latest innovations, and he praised Nano Set for solving long-standing issues in plaster performance. “So far, it’s been a great product. It hasn’t affected the workability in any negative way—some additives do cause issues, but this hasn’t at all. It really keeps the color bright and vibrant, and that’s the biggest plus for us,” Evans shared.

Another respected perspective came from Showtime Pools, who ran their own hands-on comparison between Nano and a competing product. Their crews immediately noticed the difference in the field. “I tested Basecrete Nano against a similar product. Plaster crews used both and preferred Nano for troweling and bringing the cream to the surface. Vito, hats off to you and the company all these years. I usually find new products early, and Nano keeps you ahead in the game,” Showtime Pools noted.

Mariano’s Reaction

For Mariano, feedback from respected professionals like Evans and Showtime Pools underscores exactly why Nano Set was developed. “These contractors are out there every day, and they can feel the difference,” Mariano said. “When plaster crews like Showtime say Nano trowels easier, that tells me we’re making their job better. And when guys like Jason talk about color retention and reduced scaling, that confirms we’re protecting the finish the way we designed it. The goal has always been to give applicators a product that’s easier to work with and homeowners a surface that looks beautiful for a long time. Hearing both of those points validated in the field means we hit the mark.”

Mariano explained that Nano Set works by reinforcing the plaster matrix at a microscopic level. “Once you reintegrate the matrix, the amount of dust is eliminated so you don’t have to keep brushing it down after startup. The product encapsulates the pigments and fine particles—whether that’s the Portland cement, silica fume, or other pozzolanic material—while filling in tiny capillaries to make the surface tighter and stronger. That increases PSI, reduces permeability, and protects the plaster from exposure to water, acids, and chemicals,” he said.

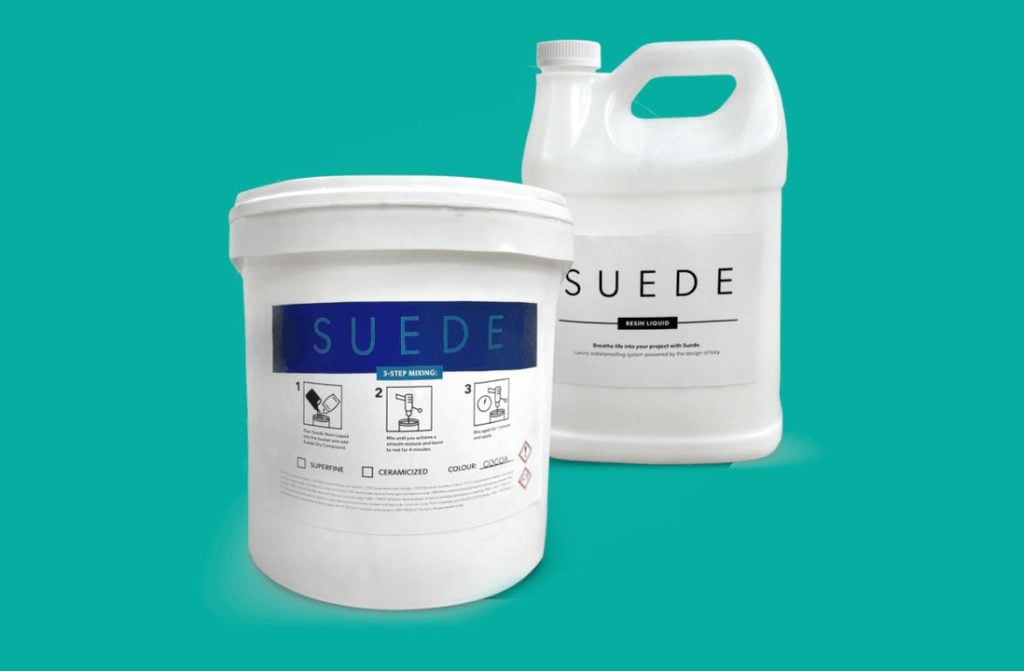

Suede Micro Ceramic: A Waterproofing Membrane with a Designer Finish

Beyond Traditional Membranes

Suede micro ceramic is being positioned as a versatile cementitious membrane that functions underwater and above water. Unlike plaster, which must remain submerged, Suede can be used across tile lines, on beach entries, and for decorative applications. “It can be exposed in and out of the water, which plaster cannot. Plaster is meant to be submerged. This product is different—we can go up and over and eliminate the tile lines,” Mariano explained.

Applications from Pools to Architecture

The system is gaining traction in applications ranging from water features and koi ponds to architectural finishes. “If you’ve ever been to Europe, especially Italy, they have the old-fashioned Venetian walls that look like suede—that’s why it’s called ‘Suede’. It has a beautiful finish and is very easy to work with,” said Mariano. The material is produced with porcelain-based aggregates, creating a highly durable surface with baked-in color that resists fading.

Compatibility with Basecrete Systems

Suede also works in tandem with Basecrete’s existing waterproofing membranes, offering flexibility for contractors seeking layered protection. “When you have a concrete wall, you want to use the base—say the white Basecrete—and then you apply the Suede. It’s like applying paint over top of drywall or concrete, but it’s troweled on or sprayed and it’s a very workable material,” Mariano said. In some markets, such as Europe, Suede is even being used inside pools as a substitute for plaster where skilled tradespeople are scarce.

Fiberglass Mesh & Basecrete Xtreme: Reinforcing the Future

A Proven Solution for ASR Remediation

Basecrete’s fiberglass mesh system isn’t just a new material—it’s an innovation already making an impact through Basecrete Xtreme, a product unveiled late last year. Integrated directly into the compound, Xtreme has been a boon for alkali–silica reaction (ASR) remediation projects, helping contractors repair compromised concrete structures with efficiency and durability. “There are about a million fibers per square inch, and it adds more flexibility to the application,” Mariano explained.

Benefits for Plaster Bonding

The fibers also improve adhesion for plaster applications. “When you plaster over top of that, the fibers hook into the plaster, which creates a much better bond to the material,” Mariano said. This mechanical bond reduces the risk of separation between plaster and substrate, a persistent problem when water is introduced.

Growing Role in ICF Pools

The system is particularly well-suited for insulated concrete form (ICF) construction, a growing segment in the pool industry. “The reason why it’s growing so much, especially in the Caribbean, is the lack of tradespeople who know how to do the work. So they’re building them out of ICF, which is insulated concrete foam. I think it’s a perfect system and it’s easy—anybody can build a pool,” Mariano said. By eliminating the need to manually apply mesh, Basecrete’s new product simplifies ICF pool construction and reduces labor demands.

Looking Ahead: A Complete System Provider

With Nano Set, Suede, and their new fiberglass mesh Xtreme product, Basecrete is broadening its role from a single-solution provider to a complete system innovator. “At the end of the day, it’s about giving contractors and homeowners something they can trust. Our job is to make that process easier while protecting the beauty of the finish for years to come. That’s been my focus since the beginning, and it’s what keeps us pushing forward to add more products to our lineup.” — Vito Mariano, Basecrete Technologies.

Ready to take a deeper dive?

Listen to our entire conversation with Vito Mariano, President of Basecrete Technologies, on the Pool Magazine Podcast.

The post Basecrete Introduces Three New Products Poised to Reshape The Pool Industry appeared first on PoolMagazine.com – Get The Latest Pool News.